view allProduct List

Latest Add

Contact Us

TT-H12C High quality automatic big heavy Toroidal winding machine replace Jovil, Gorman, Ruff winding machine

TT-H12C High quality automatic big heavy Toroidal winding machine replace Jovil, Gorman, Ruff winding machine

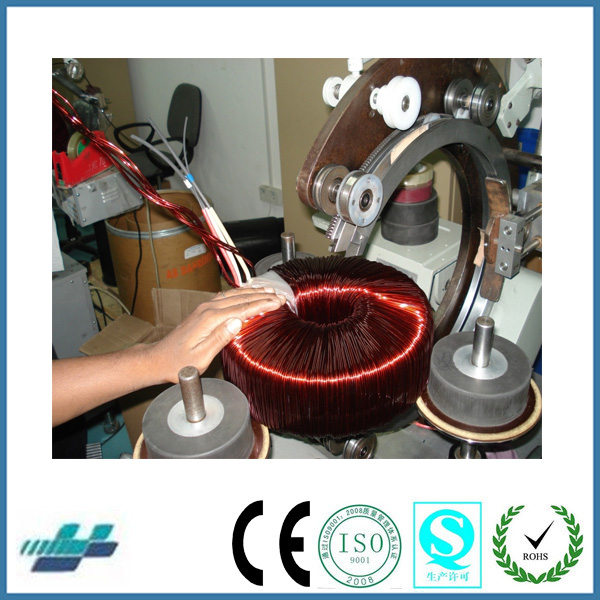

TT-H12C automatic Toroidal transformer winding machine

Features :

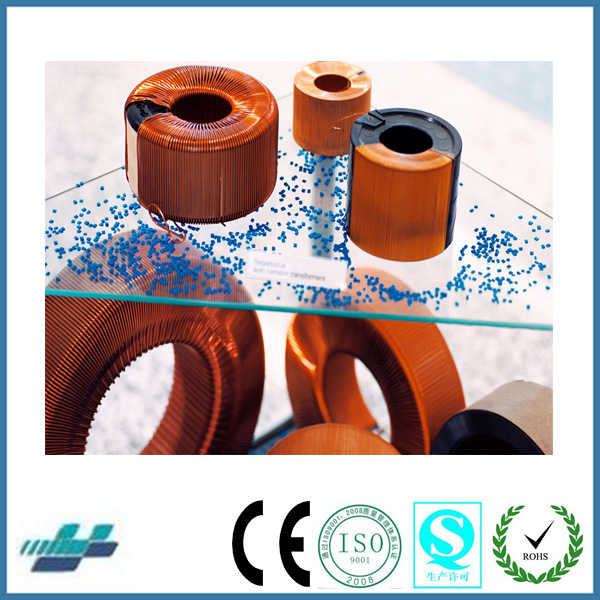

• TT-H12C automatic Toroidal transformer winding machine adopts CNC toroidal controller, TT-H12C automatic Toroidal transformer winding machine is Gear type Toroidal transformer winding machine . TT-H12C automatic Toroidal transformer winding machine is an accurately and reliability digital Toroidal coil winder , TT-H12C automatic Toroidal transformer winding machine is used for toroidal inductor, toroidal transformer, toroidal current transformer, toroidal current sensor, toroidal coil, toroidal chock coil, power inductors, power magnetics, UPS inductor, converter inductors, watter metter sensors, toroidal current transformer of electronic watter-hour meter etc

Machine Type | TT-H12C Toroidal transformer winding machine |

WIRE SIZE | 0.6-2.5mm |

| SHUTTLE DIAMETER | 266mm |

MIN.FIN. I.D. | 42mm |

SPEED | 200RPM |

COIL O.D. | 50-254mm |

MAX. HEIGHT | 152mm |

WINDING MOTOR |

0.75KW AC motor, variable frequency drive

|

POWER SOURCE | 220V ±10%; 50 / 60 Hz |

Net weight | 95KG |

Dimensions | 950mm X850 mm X900 mm

|

1. Collocate the gear type winding head to wind very heavy wire, and interchangeable roller table with different size shuttle(magazine) for different dimensions coils and different wires, so that to reduce the cost.

2. Hi-tech shuttle for highest efficiency.

3. Separate speed controls for loading and winding.

4. Accurately count length of loading by limited-switch.

5. Accurately count turns of winding by photo-electricity sensor.

6. Programmable winding direction, winding returns range (Turns or Angle) and segment winding angle.

7. Accurately wire spacing by programmable controller

How to select the best suited automatic toroid coil winding machine for your toroid coil

Tell us your toroidal coil of data as below please:

1, toroid core outside diameter before winding?

2, toroid core inside diameter before winding?

3, toroid core height before winding?

4, how many windings on this core?

5, how many turns of each winding?

6, how about the copper wire diameter of each winding?

7, provide pictures of product which is better.